01 / 03

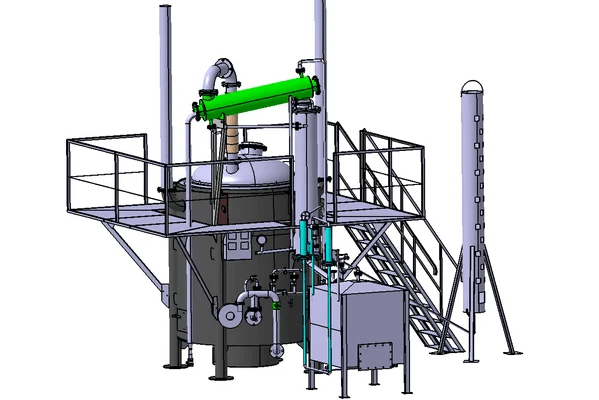

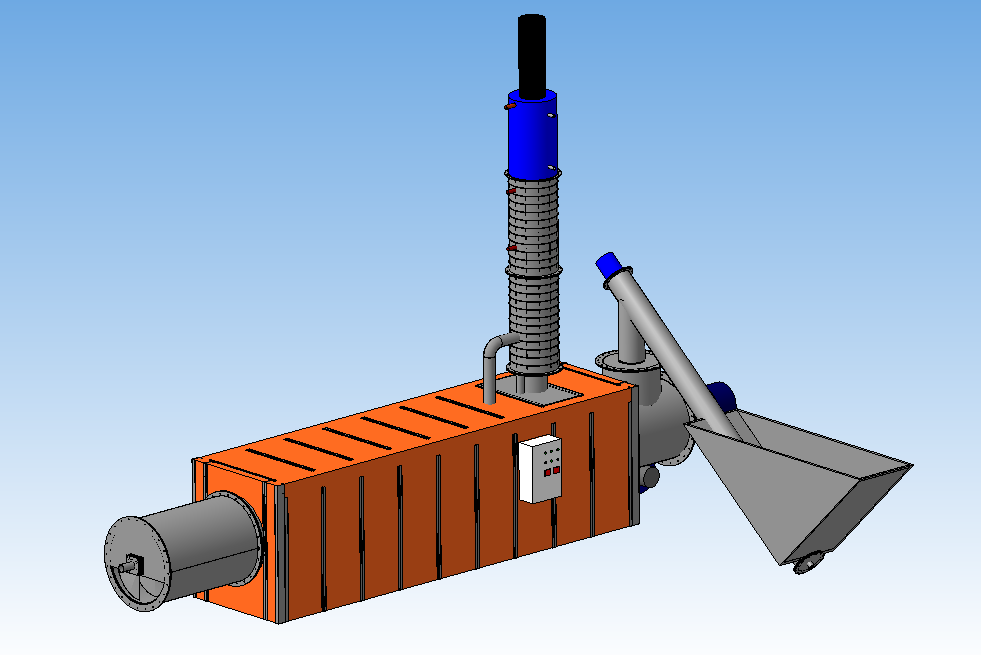

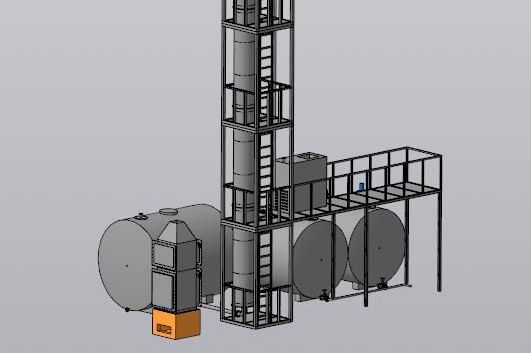

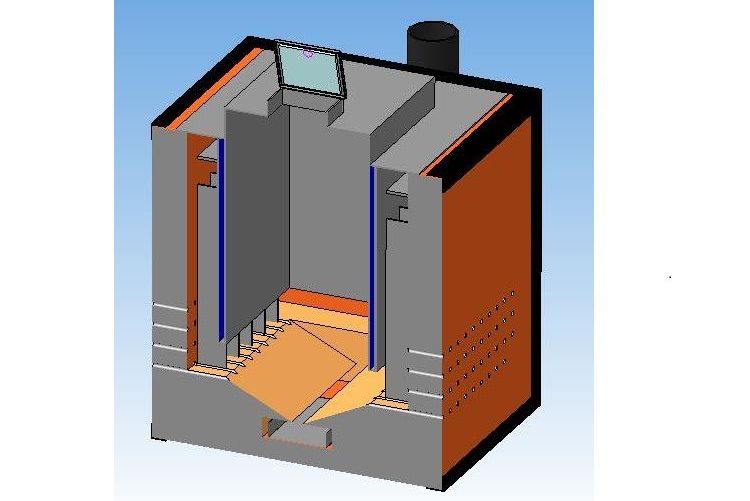

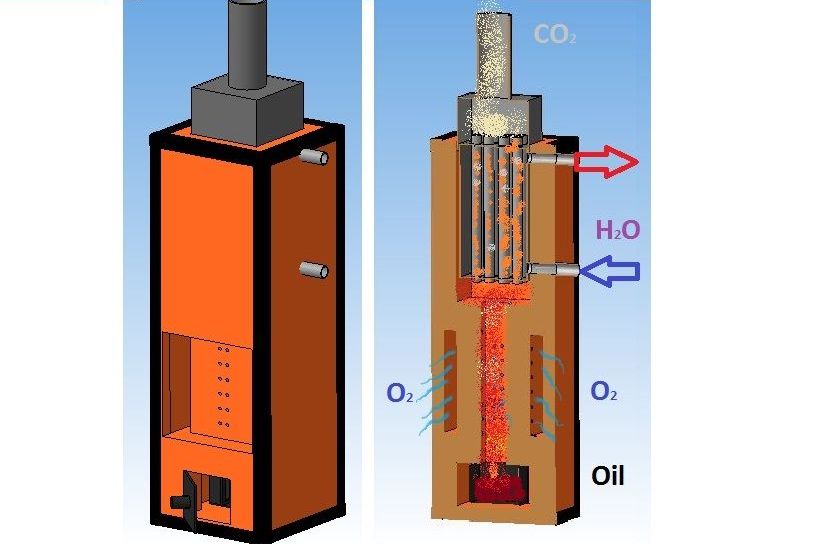

+ Simple retort design

+ Low price

- Cyclic operation. Low efficiency

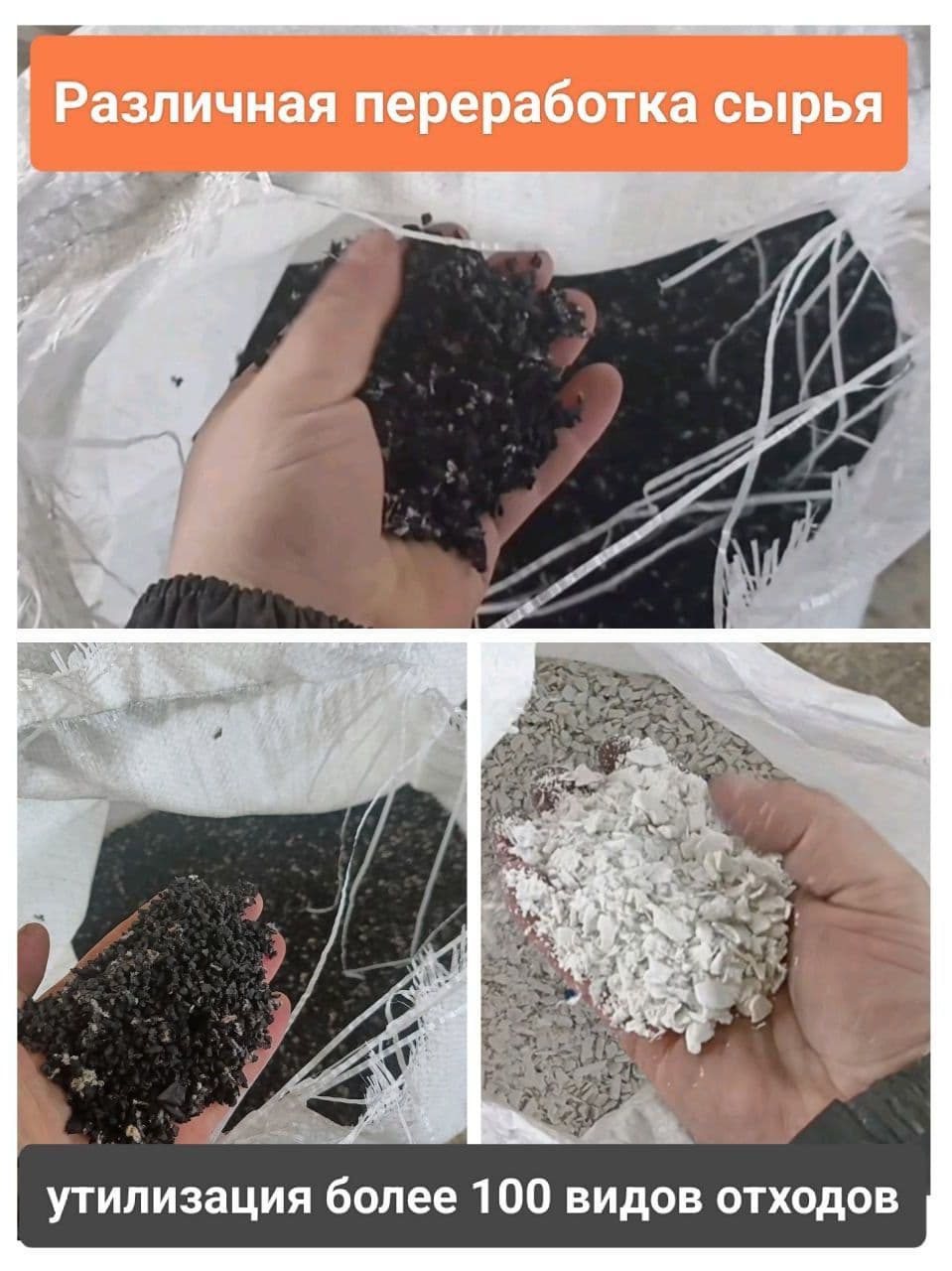

- Incomplete processing of raw materials

- Limited retort volume

- Long process time

- High energy consumption

EFFICIENCY 50%

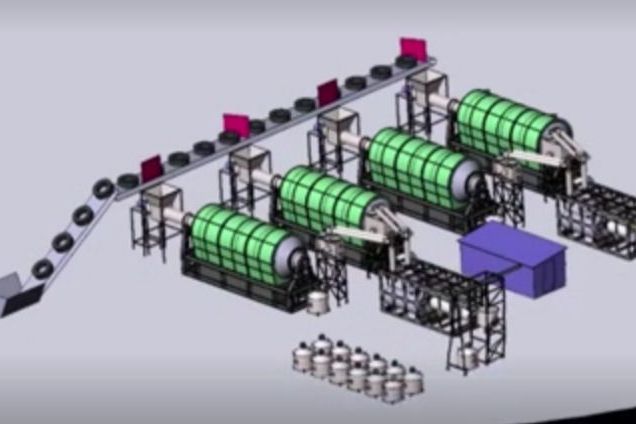

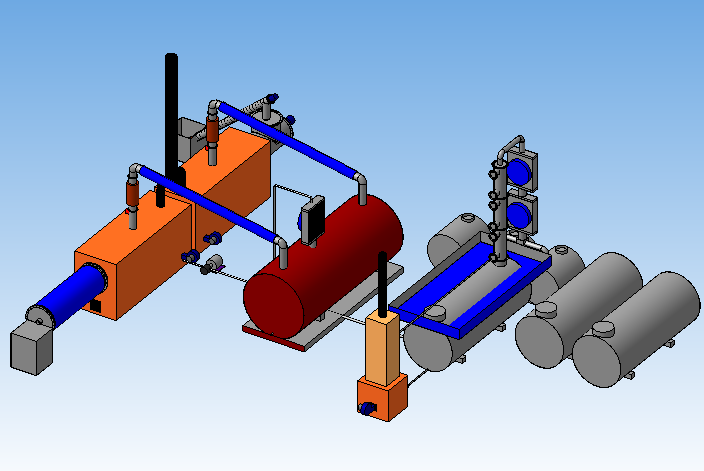

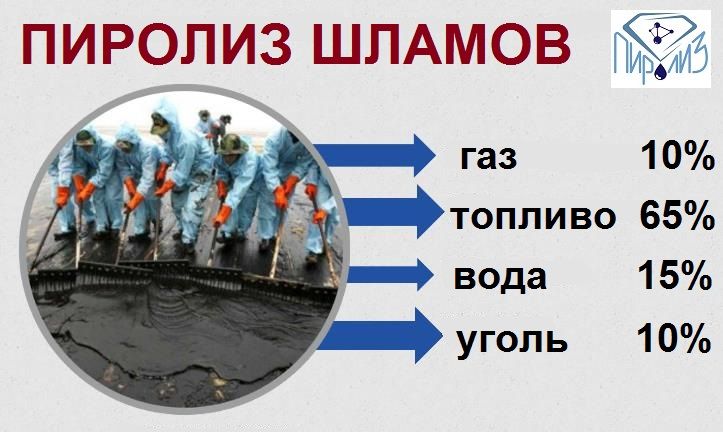

+ Low price

- Cyclic operation. Low efficiency

- Incomplete processing of raw materials

- Limited retort volume

- Long process time

- High energy consumption

EFFICIENCY 50%

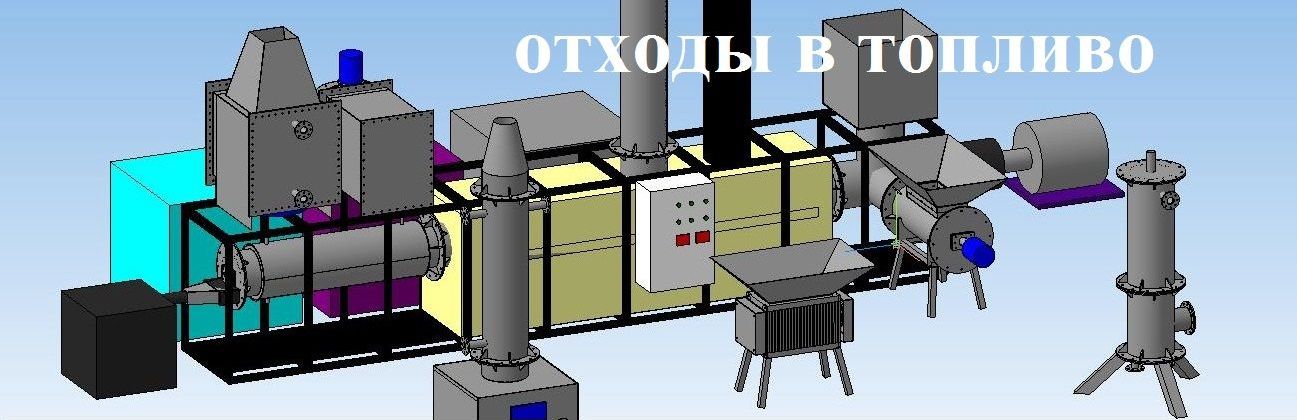

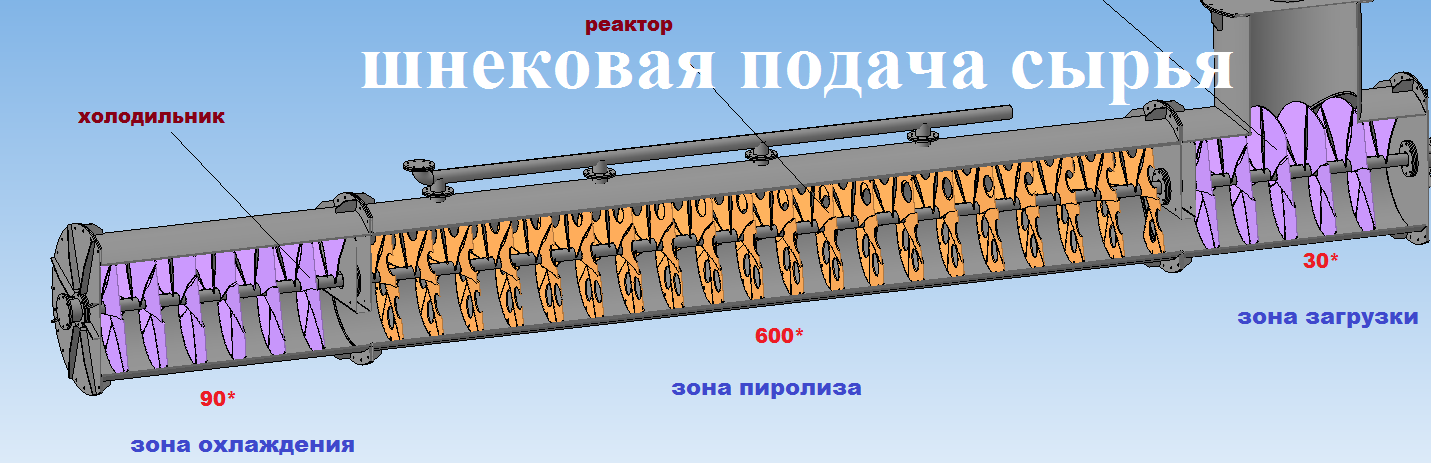

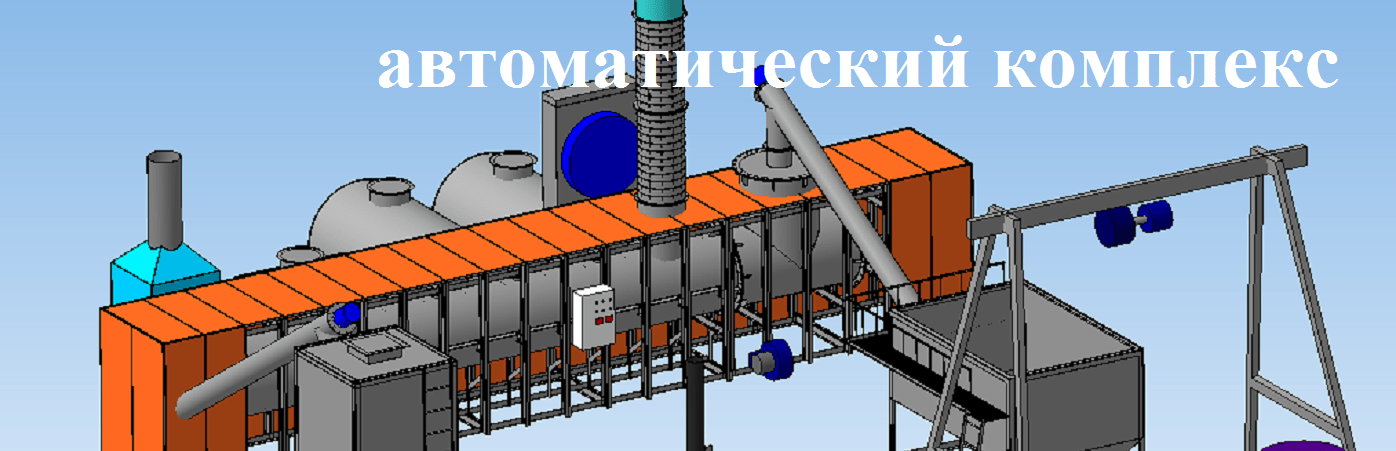

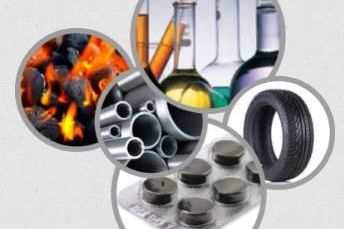

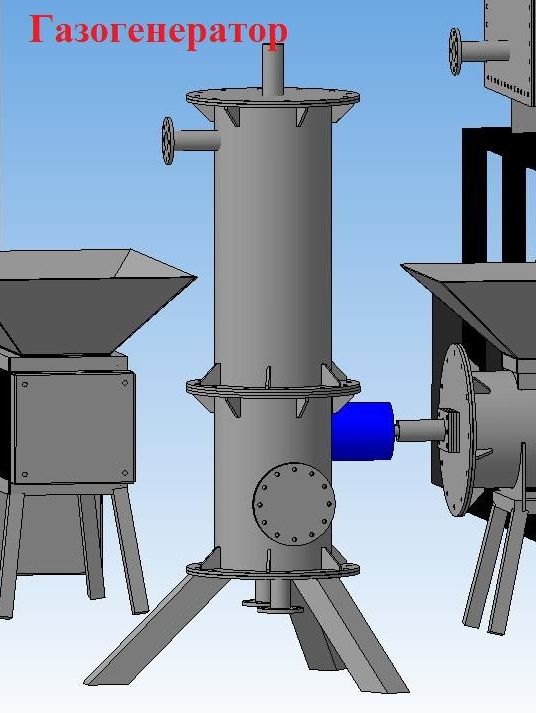

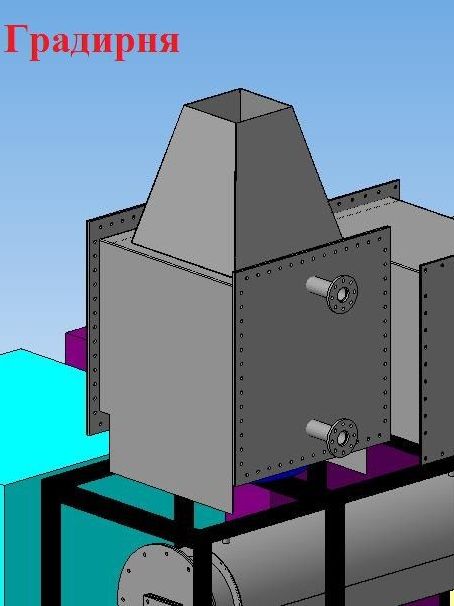

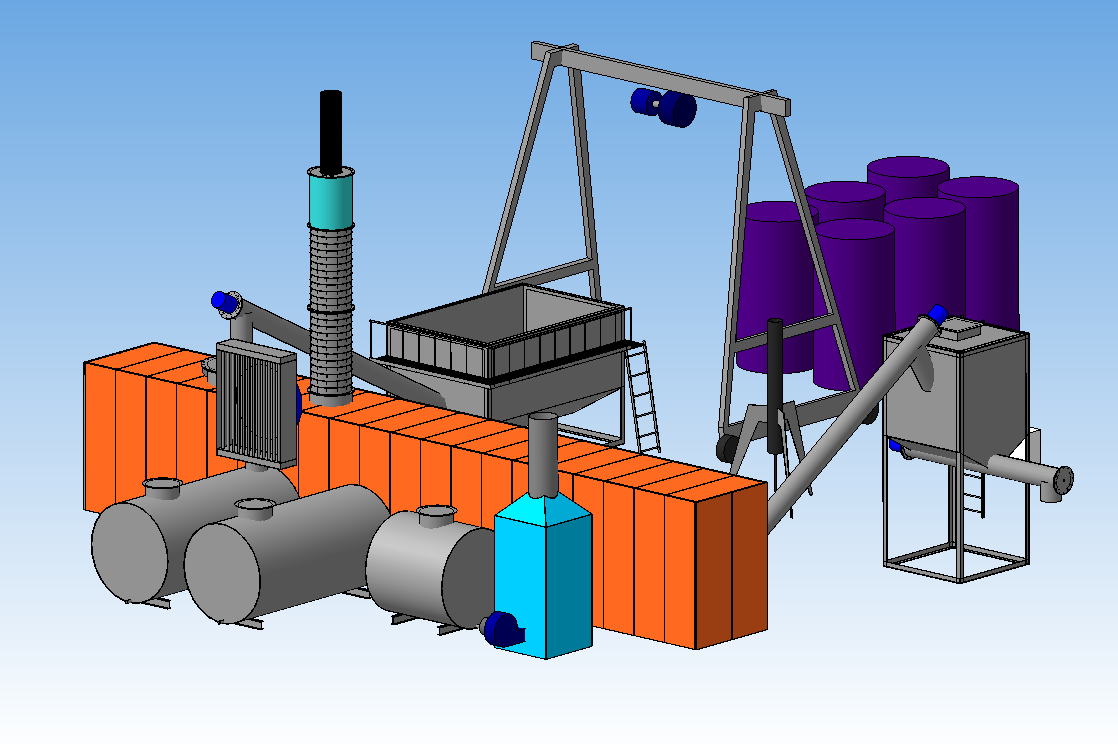

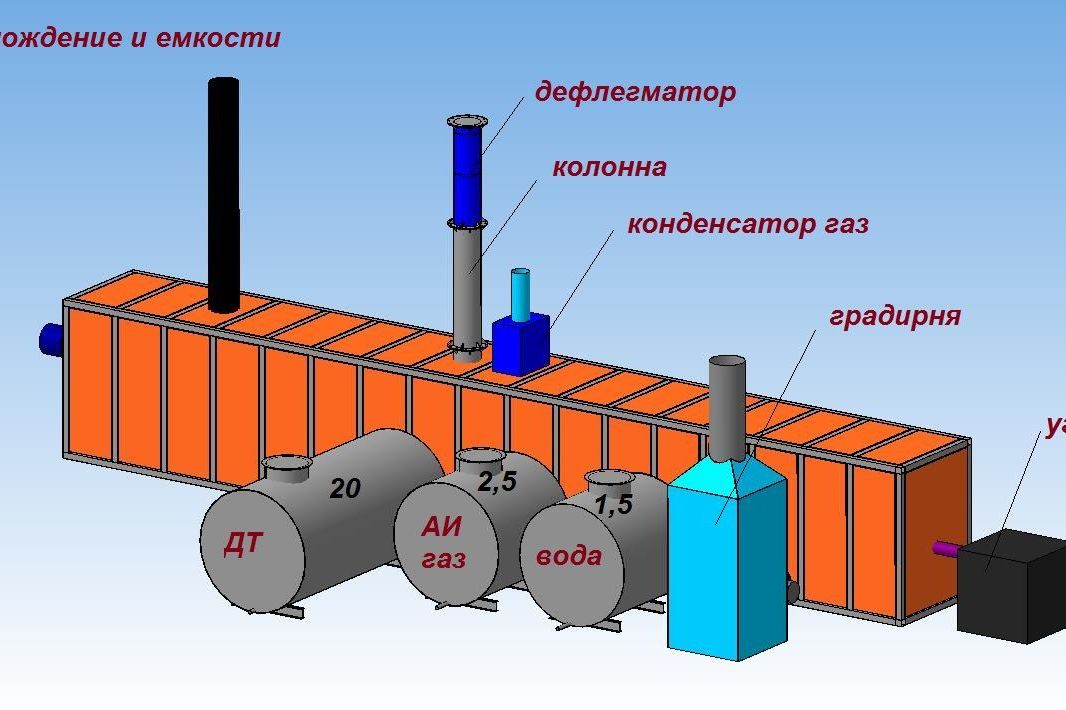

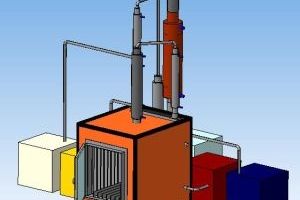

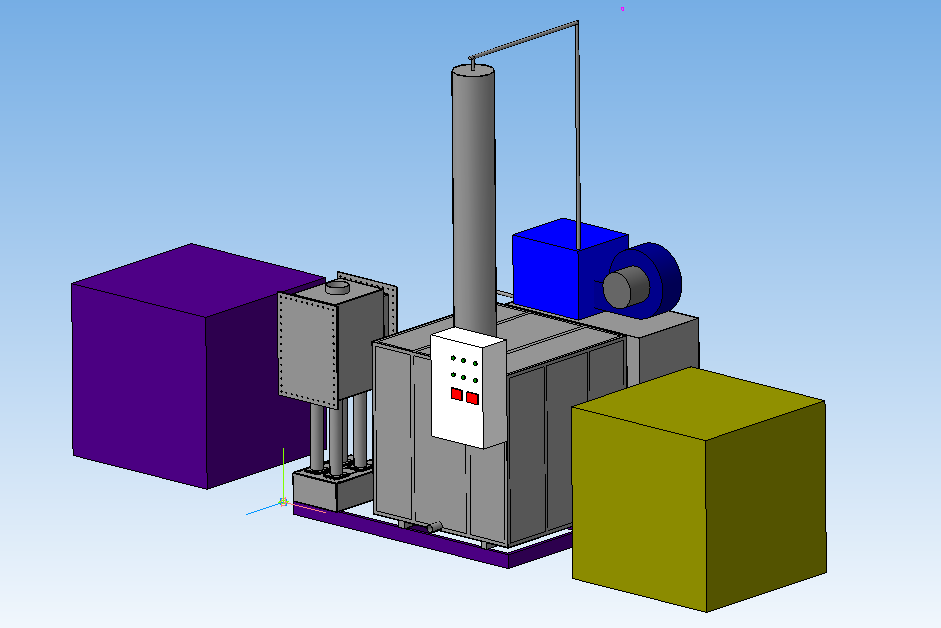

Choosing the right installation with the right retort design will help you efficiently process raw materials into fuel.

Chief Engineer Pyrolysis LLC